The solution of vehicle charger for electric vehicle

2017-03-22 11:49:51 Source:Shenzhen YLZ technology co., LTD Author:YLZ-温 Visit:1081

With the aggravation of environmental pollution, new energy is playing a more and more important role in people's daily life. The market share of electric vehicles is becoming bigger and bigger. But the electric car can not run too long because of the limitation of battery capacity. Therefore, electric vehicle charging pile is becoming more and more important. There are two types of electric vehicle charging pile, namely, DC charging pile and AC charging pile. DC charging pile has higher power, can output DC voltage, but the cost is too high, therefore, the number of AC charging pile is much larger than the DC charging pile. However, AC charging piles need to be used with the car charger. For car charger solutions, most customers will choose the two level power architecture. The first stage is PFC (power factor correction) boost converter, the second is PSFB (phase shifted full bridge) or LLC converter. Because the PFC output voltage is always constant, when the system output voltage range is not large, the customer will choose a more efficient LLC converter.

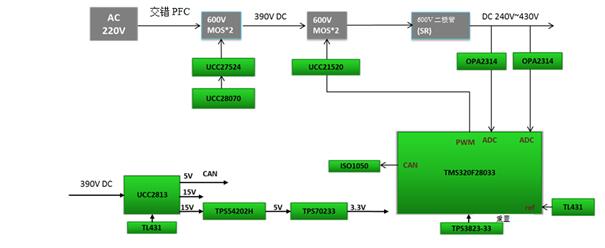

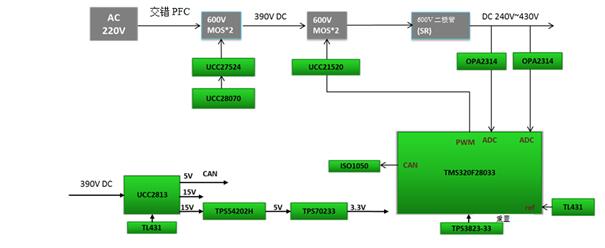

For PFC level, TI has many solutions. For example, the UCC28070 is interleaved with the PFC controller, which integrates two interleaved 180 degree pulse width modulators (PWM). Reduce the input and output current ripple, and reduce the size of the capacitor. It also reduces the cost of conducting EMI filters by interleaving techniques and programmable frequency dithering techniques. In addition, the device also can be used in the design of a double boost bridgeless PFC, its efficiency is more than 1% higher than the normal PFC. UCC28180 is an easy to use 8 pin CCM (continuous conduction mode) PFC controller. The controller is similar to the single cycle control technique, which has a good transient response, and can obtain a lower than 5% THD index under full load conditions. Customers can also use the totem pole PFC TMS320F28033 designed to achieve high efficiency and good EMI performance.

For PFC level, TI has many solutions. For example, the UCC28070 is interleaved with the PFC controller, which integrates two interleaved 180 degree pulse width modulators (PWM). Reduce the input and output current ripple, and reduce the size of the capacitor. It also reduces the cost of conducting EMI filters by interleaving techniques and programmable frequency dithering techniques. In addition, the device also can be used in the design of a double boost bridgeless PFC, its efficiency is more than 1% higher than the normal PFC. UCC28180 is an easy to use 8 pin CCM (continuous conduction mode) PFC controller. The controller is similar to the single cycle control technique, which has a good transient response, and can obtain a lower than 5% THD index under full load conditions. Customers can also use the totem pole PFC TMS320F28033 designed to achieve high efficiency and good EMI performance.

For second, if the output voltage range is relatively wide, TI has a special UCC28950 do PSFB to achieve. Compared with UCC3895, the chip has many advantages. For example, synchronous rectification MOSFET output, SR output of the adaptive delay, no-load burst mode control, slope compensation, etc..

With the MOSFET conduction impedance becomes smaller and smaller, the total loss of conduction loss is getting smaller and smaller, LLC relative to PSFB to become more popular. For LLC, you can use UCC25600+UCC27714 to design the converter. Because the electric car charger needs to communicate with other systems. So the general customers will choose C2000 chip to design half bridge LLC DC/DC converter.

Here is a basic block diagram of the TI solution.

For second, if the output voltage range is relatively wide, TI has a special UCC28950 do PSFB to achieve. Compared with UCC3895, the chip has many advantages. For example, synchronous rectification MOSFET output, SR output of the adaptive delay, no-load burst mode control, slope compensation, etc..

With the MOSFET conduction impedance becomes smaller and smaller, the total loss of conduction loss is getting smaller and smaller, LLC relative to PSFB to become more popular. For LLC, you can use UCC25600+UCC27714 to design the converter. Because the electric car charger needs to communicate with other systems. So the general customers will choose C2000 chip to design half bridge LLC DC/DC converter.